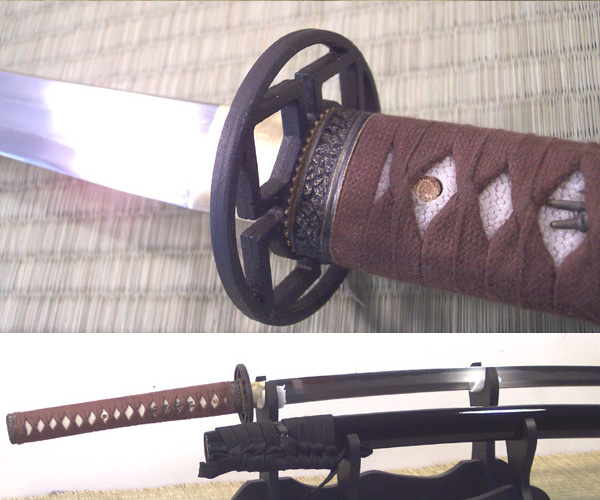

Cheness 9260 Differentially Hardened - "Kaze" Katana

DISCONTINUED

SOLD OUT & UNAVAILABLE

Differentially Hardened Blade with REAL Hamon. Available with Black or Brown Ito.

Hand clayed and differentially hardened, what makes the Kaze unique is the use of the revolutionary 9260 Spring steel: a perfect combination of age old art with cutting edge modern metallurgy giving it a beefy but extremely sharp blade.

Unlike just about every other production sword on the market in this price range, the Kaze has a totally authentic, unenhanced Hamon temper line (other production swords typically all have acid etching or wire brushed hamon). While the hamon is subtle (as the polish to bring it out to its full potential would double the cost of the sword) the 9260 Spring steel results in a very distinct pooling of the nie crystals, making for a nicely defined hamon line.

The fittings include a blackened steel replica of an actual antique tsuba, one brass menuki peg for additional tsuka structural reinforcement over the full tang and thick tsuka with real rayskin panels housing the blade that cuts traditional targets like a laser, which is why I have nicknamed it 'the Tatami Killer'.

For more information and test cutting results on the Kaze, check out the full review here on SBG.

Great value, one customer described it as "One third of the price of a Hanwei Great Wave ($945) but just as good"

MUST READ NOTE REGARDING CHENESS CUTLERY SWORDS

Cheness Cutlery Swords are designed by Martial Artists for Martial Artists. Their goal is and always has been to simply offer an affordable entry level practice sword to beginners in iaido and iaijutsu and when first released in 2005 truly revolutionized the sword market for until that time, there were few to no entry level Katana.

Cheness swords were never meant to be collectors pieces, display pieces, or art sword quality. There are numerous other manufacturers and individual smiths in the industry that serve those needs (click here for our full selection of Japanese swords). The reason being the same as with all other hobbies, refinement will come with a price.

Because of this, certain shortcuts must be taken in the manufacturing process and are NOT considered to be defects. Because of this, we will not accept returns on any swords that have the following features:

- The polish of each sword is a working polish known as a 'Tameshigiri' polish and is somewhere between 400 to 600 grit. As they are handmade and subject to extensive handling, they do get scuff marks and minor stains on the blade and components.

- Each blade is hand hammered, shaped to the eye, and then tempered and quenched. This process causes all types of steel to contract, twist and warp to some degree -with 9260 being one of the hardest steels to keep straight - so you should not expect the blade to be perfectly straight like a lazer. Even if slightly off center or imperfect, it will still cut perform for Tameshigiri and you can be confident in the tempering.

- The blades have considerable hira-niku (meat) on them for heavy cutting and will generally feel somewhat dull to the causal observer. It will not slice paper or shave hair off your arm. It WILL cut tatami mats or bamboo or other targets that were traditionally used to simulate human limbs. With only a little work however, it is quite possible to sharpen it to any degree desired.

- The cotton ito wrap is tight enough for use, but is not going to be as tight as silk or leather. Habaki, Seppa, Fuchigashira, etc are free floating and pinched into place by friction forces like a traditional Katana, but some minor adjustments may be necessary out of the box.

- Mekugi pegs are angled by design to create a wedge and optimize the double mekugi configuration. The bottom peg is made of brass, the top, bamboo which results in an overall stronger design and was recommended by a senior Japanese JSA Sensei.

In short, you should not expect an art sword or something perfect out of the box. You will almost certainly need to make some adjustments or even a complete DIY overhaul (we have many free tutorials on how to do this right here on the main SBG website). But for those of you who don't mind a rough and ready sword, or who wish to take it to a higher level, you will find these blades to be extremely long lasting, tough and worth every penny.

In summary, Cheness puts it like this:

The issues can all be addressed by the end user if they so choose. After receiving the sword, you can adjust the components, add a high-grit diamond paste polish, deburr the blade to slice paper, polish the components, etc. to make it as refined as you choose. However, these are not the features we strive for and should not be expected of the sword out of the box. If a highly refined sword is what you are after, you will either need to be prepared to perform these refinements yourself or should purchase a higher end sword from a different manufacturer.

Please note, as to be expected issues like cracked blades, broken handles, etc are of course subject to our standard warranties and return policies.

How to Use

Materials and Construction

Warranty Info

Return Policy

Featured positive reviews:

This is my first real Katana. Purchased after reading reviews on SBG and couldn't be happier. The Kaze is a great sword. Great Balance and solid. I haven't used it for cutting yet, as I want to be sure I can cut very straight before an attempt, but the sound it makes while cutting air (The Kaze sound) is crisp. It has a good weight and is pretty solid. I went with the brown Ito wrap and it looks really nice. I would recommend this to anyone that wants a "real" differential hardened blade and doesn't want to spend thousands.

I have heard people say 9260 steel is not perfect for a differential hardened blade, but if you know anything about how Japanese Sword Master-Smiths "make" their swords - they actually pick lumps of raw-iron "steel" based on the color and the feel. Then they forge and fold that steel to remove impurities. Thus 2 swords side by side can have vastly different carbon content in the construction of the steel as the method used to chose the steel is based on feel and looks not scientific evidence. Not trying to knock the Master-Smiths that do this, they are true masters... But it is worth noting that 9260 steel is solid with a consistent carbon content from blade to blade.

Add to all of that the fact that the blade is a thick no-hi 2lb-9oz cutter and you have a solid modern version of an old sword. I think it is the best of all worlds.