Thanks to everyone who emailed me their words of encouragement about continuing the SBG Custom Katana series. Batch 21 is not quite all shipped out yet – the majority of the swords have come in and been accounted for, but we still have some stragglers that are due to hit customs this week, so we will be working to get these in and out to their owners as soon as possible.

Anyway, during this period we have been talking with the forge – trying to determine how to reduce the recent spike in the error rate (we used to have an error rate of around 3-5% per batch. When we added all the new options, the first time around it jumped slightly but was manageable. But batch 21 has had an error rate of around 10%, which is totally unacceptable and causes massive delays to correct it).

As mentioned in the previous post, we were looking at 3 options:

1) Raise the prices significantly and reduce the number of orders per batch.

2) Refine the concept, offering less but better options with a small to moderate price increase.

3) Call it a day.

From all the emails of support I received, option 3 is looking less likely. I want to keep offering this line, but I need to find a way to make it work better and to improve it substantially.

Option 1 is tempting – but it’s too elitist for my taste. So that leaves us with option 2..

To this end, I had been talking with the forge about how we can refine the custom Katana to reduce the error rate, improve the quality – without a massive price increase for a base model custom Katana (though there will HAVE to be a price increase to factor in previous cost increases that we did not pass on and the additional cost of better quality components).

Anyway, I think we might be getting somewhere..

Here is what it is looking like:

- 3 blade lengths, 27, 28 and 29″. All standard Shinogi Zukuri.

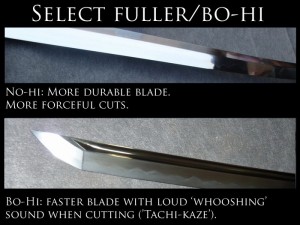

- Bo-hi (improved) or no hi.

- Limited selection of IRON tsuba and iron fuchi/kashira

- Limited selection of brass or copper themed sets

- Current selection of ito colors

- Current 12 selection of saya colors

- Limited number of optional upgrades

To explain this a bit further, because our forge is a very small one it did not have access to all of the components used by other sword makers on the market. We were initially limited to a handful of brass tsuba, 7 iron tsuba – but a large assortment of basic alloy tsuba and fuchi/kashira.

But in the recent negotiations with the forge, we have managed to secure a decent selection of IRON tsuba with iron Fuchi Kashira and I’ve been playing around with how to make it work..

Here’s an example of 6 of the 31 possible iron tsuba we have been able to secure.

All 31 have a black base powder coating, and so do the matching Fuchi/Kashira sets of which we will only have 4 options, but mixing and matching them with the tsuba guarantees they will not clash.

Of course, the main benefit of using iron components is a huge increase in the swords overall durability and longevity and it is what I would want if I was making it for myself.

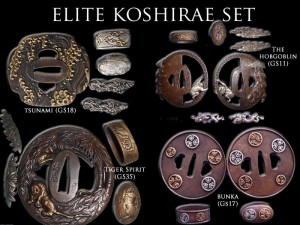

Anyway, this will be the basic option – but there will also be an option to upgrade to a brass or copper set which has pre-matched, themed components like this one that we use on our USA based sword customization service.

(this is an example only, I don’t yet know what kind of sets we will offer or how much extra it will cost – but they will be sold as is, no mixing or matching).

Combine this with 3 selected premium upgrades (rayskin on the saya, folding and leather wrap with hishigami) and I think we may have a valid custom Katana that is actually better than the original custom Katana series.

The error rate should come way down again and the price increase, while it will happen, will not be a jump of $160 or so.

I should also mention that the bo-hi option will be a proper bo-hi with correct termination at the kissaki as pictured below.

If we were to proceed with this, I think that we may be able to not only continue the project, but give it a whole new lease on life. But due to the need to avoid errors and cut down the production time, we will not accept any customizations that fall outside of the options we have chosen. It just messes up the whole thing, confuses the forge and upsets the end customer when something goes wrong.

Now like I said, this is all in the early stages – and I cannot guarantee that we will be able to pull it off. Indeed, in many ways it is a return to the basics – but with the experience of several years behind us, numerous refinements to the base product (such as really nice kissaki, alternating ito, etc) I think that if we are to continue, this will be the shape of things to come..

In the meantime, it’s back to bringing in the last of batch 21 and tying up the loose ends. But once this is done, maybe this is the fresh start the project needs..

I’ll keep you posted.

– Paul