The new Forge for Project X in short, totally rocks. Fast and precise work with high QC and exceptional value for money.

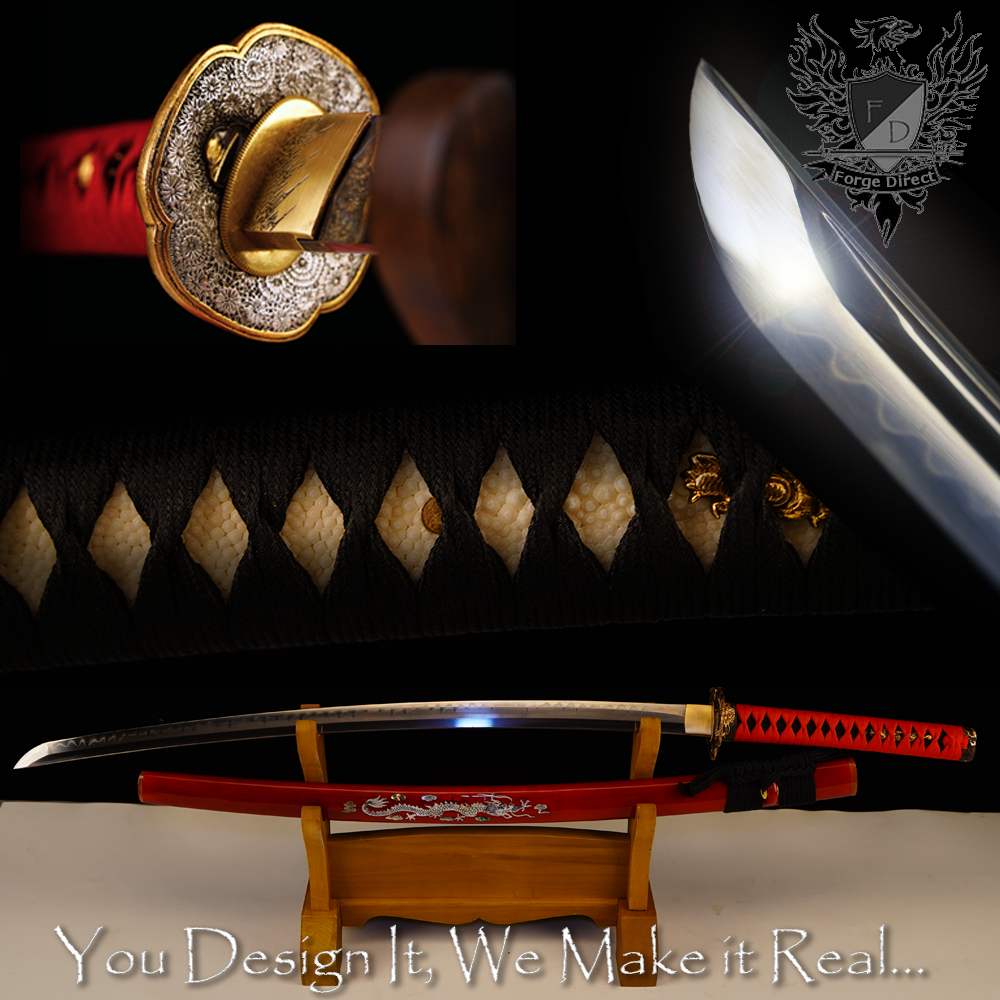

Here’s some recently completed customer design pics so you can see what the design combinations can create..

NOT FOR SALE – Customers Orders Images

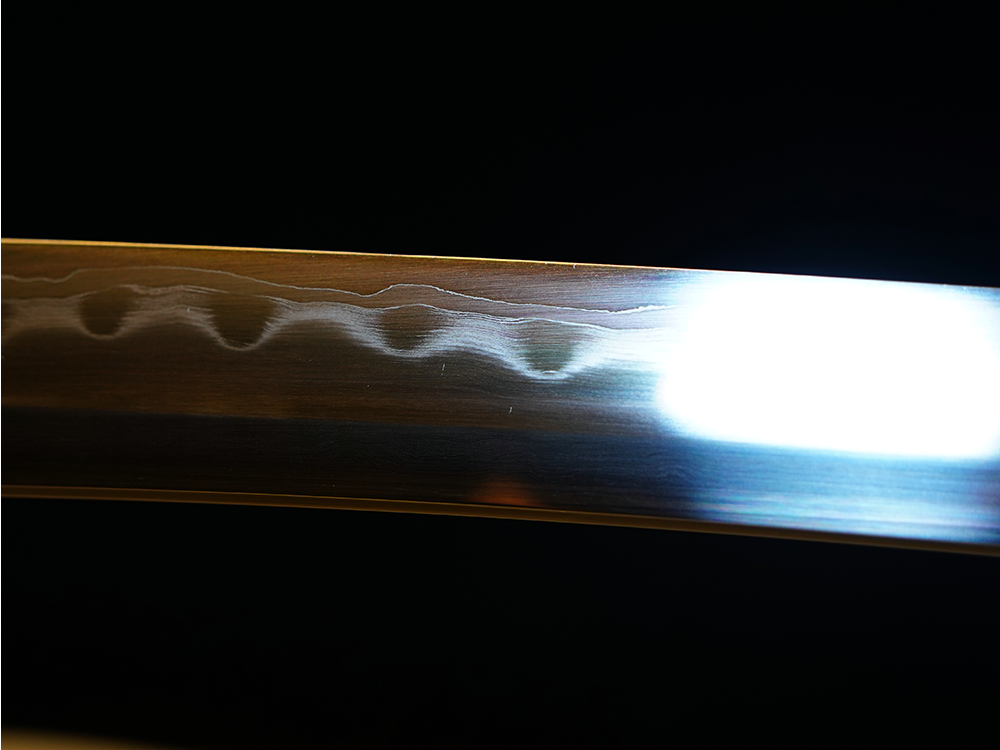

You can see the detail of the complex interplay between lamination lines and hamon, buffalo horn jokiri and kurikata, premium silk sageo. Nice and subtle functional style.

Lovely choice of subtle earthy colors on this one, basic T10 blade.

Musashi iron tsuba, lovely ito and the full rayskin wrap that comes for free with EVERY Project X sword.

Subtle or eye catching, this is is definitely the latter. Free raysking wrap upgrade on the saya, work hardened copper 24K gilded gold and silver fitting set based on an actual antique. Its your sword, so why not make it POP!

EVERY Soshu Kiate blade is unique like a fingerprint. This one has a lot of a activity and is hard to look away from.

Just another laminate blade version highlighting the hand carved bo-hi and geometric kissaski.

Black on black always looks super cool and mean. Add a little splash of detail to the habaki and its set.

And if you wanna go extra mean, try black leather ito! It’s tough, hard wearing and very bad boy..

Eagle themed fitting set makes this design positively soar.

Just as lotus leaves lead to enlightenment (well, that was the idea!)

Back to the subtle is best theme, the classic iron sunburst shifts the weight forward for heavier cutting, and looks cool as hell with that habaki and brown ito.

Just a close up of the lamination. You an see its not just san-mai, this is the real deal..

And it’s not just Katana, Wakizashi and Ko Katana – not to mention matching Daisho sets are always popular and a real bargain.

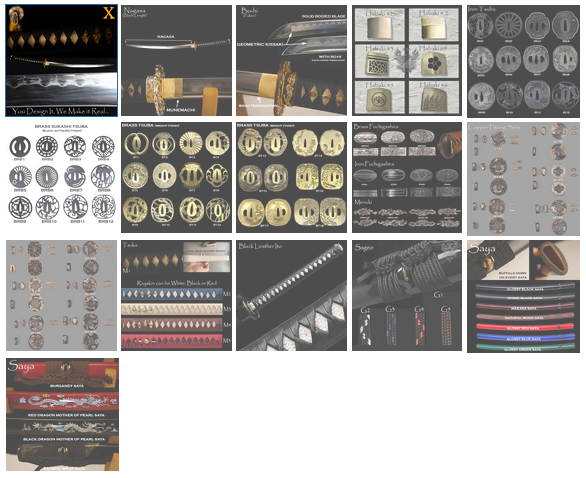

They aren’t for sale, but if you want to try your hand, have a look at the options. One flat rate price for everything.

Always fun to see a bit of behind the scenes stuff.