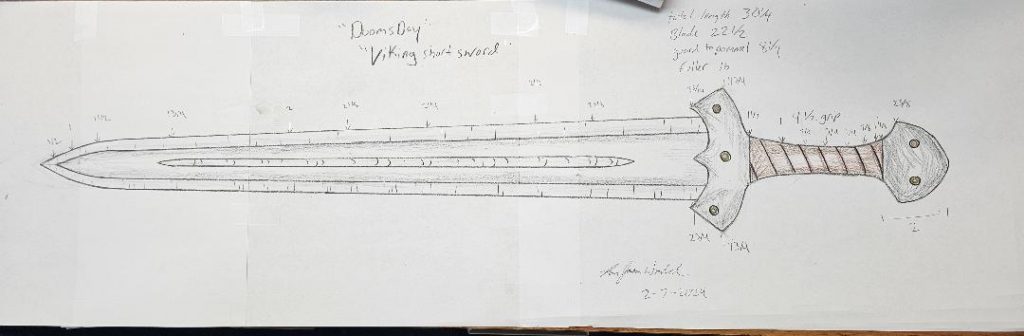

It is the second Ragnarok inspired Viking blade in Jason Woodards Doomdsay Sword series and the second with a curious fusion of ancient Norse design with modern materials and blade making techniques – starting as it always does with a 1:1 scale sketched design.

After careful consideration of the overall design and individual design elements, Chris Palmer then creates and has cut out a Master Template in 1095 carbon steel.

The blank has some basic edge geometry ground in and the handle is drilled in 11 places where pins and epoxy will later bind the handle to the steel.

Edges are further refined and a narrow fuller is ground along the center of the blade on both sides, providing it it’s general shape and styling.

The entire blade is then heat treated to around 1500 degrees and then quenched in brine, hardening it, before the steel is heated a second time to approx 500 degrees and allowed to temper.

The tempered blade is cleaned up and polished, and has two blocks of Black Linen Mircarta pinned and epoxied on both sides in a classic hard wearing sandwich tang construction.

From there, the handle is ground to shape and has 5 additional brass pins inserted, for one of the strongest blade to handle and overall strength swords currently on the market,

Finally it is all cleaned up, the blade is given it’s final edge, the handle gets wrapped in deer leather (and if ordered, the optional scabbard is fitted and made).

And the end result, Doomsday Sword #10 – Viking Type 8, now available at the SBG Sword Store for just $279.99

Not bad for an entirely made by hand in the USA blade!