At the SBG Sword Store we offer three different brands and three different levels of customized katana. Click on any of the links below for the full run down.

TIER I and TIER II BLADES WITH TIER I FITTINGS

RYUJIN CUSTOM KATANA (and Wakizashi)

Basic entry level T10 Tool Steel blades with basic entry level fittings (price range $200-500) that are assembled to order and shipped out within a week from the Ryujin California workshop. These are the most affordable and fastest to make and ship custom Katana on the market.

TIER III BLADES WITH TIER III FITTINGS

FORGE DIRECT CUSTOM KATANA (and Wakizashi)

Master Smith forged, high performance T10 Tool Steel Custom Katana (price range $700). Best balanced between value for money and overall build quality. Typically ships in 6-8 weeks. Made entirely at and shipped from the Forge.

TIER IV BLADES WITH TIER III FTTINGS

PROJECT X CUSTOM KATANA (and Wakizashi)

Master Smith forged, complex laminated (Soshu kitae: 1095/1060/1045 carbon steel layers) and high polish T10 Custom Katana (price range $850-1000). The fitting sets available are the same Tier III sets for Forge direct, but the blades are the highest tier/level possible (Tier IV).

SIDE-NOTE: We also used to offer the SBG Custom Katana from 2008, but for now and indefinitely this product is on hold.

In the meantime, let’s do some comparison between the different lines available.

Each line has a lot in common, as the blades and components are all made at a single forge – but at different levels of build quality depending on the brand and the model.

In this article we will take a detailed look at:

- what to expect from each custom Katana line

- why the different price points

- a general comparison as well as pros and cons of each line and..

- everything else you need to know to be able to make the most informed choice possible as to which line best suits your own unique needs and requirements.

So without any further ado, lets get started..

First off, the similarities

One common feature on our custom Katana lines since the beginning has been the frequent use of T10 tool steel. Only one of the elite Project X blades are not made with from differentially hardened T10 tool steel. The amount of blade polish, the style of hamon and the overall quality will vary depending on the brand and sword selected – but this steel is our go to choice for our entry level and mid to high level offerings.

Why? Simply because I have found over the years that T10 tool steel is very strong for a differentially hardened traditional style blade. But it also tends to produce a very prominent hamon temper line that when polished to perfection is very crisp and attractive.

In terms of strength, we have tested T10 tool steel swords on a large variety of targets, from saplings, super thick bamboo, pork leg bone and meat, to metal poles, 55 gallon steel drums and in every case the blades have held up incredibly well. You can see this testing in our review of the Ryujin line here and the SBG custom line here – but to cut a long story short, this steel holds up much better than any other steel type when it comes to a traditional blade, most of which are not really all that strong – but T10 just works really well for a dual tempered blade..

Here is some of the earliest testing I did that showed just how tough this stuff can be:

Additionally, T10 takes and holds a very keen edge – making it tough but also capable of very precise cutting. But it also LOOKS great – the hamon is always prominent, though how prominent, its style and how well polished depends on which custom line you go with..

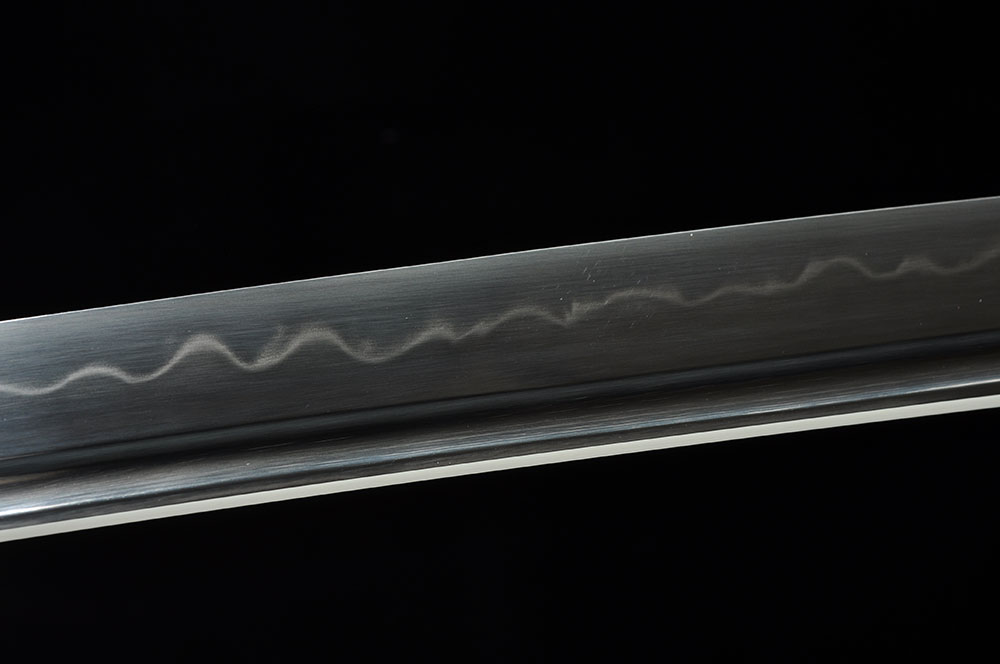

The basic Ryujin Polish when photographed from just the right angle looks something like this:

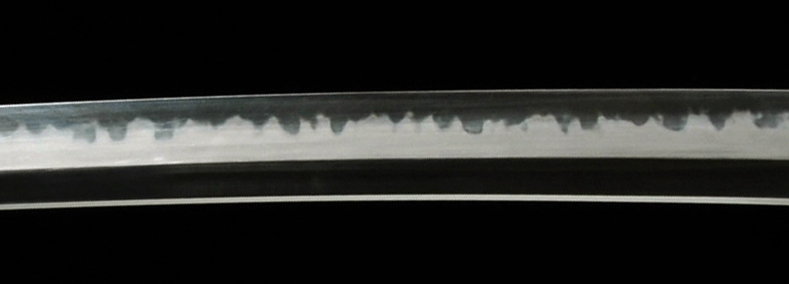

Not bad considering the sub $300 price tag, and that mostly comes down to the qualities T10 has mentioned earlier. But look at what happens when the same steel is worked by the Master Smiths from Forge Direct:

And it gets even better and is taken to the highest level with a Japanese fingerstone polish with Project X.

So how nicely it turns out depends on who makes it and the corresponding price paid – so its no real surprise, you get what you pay for.

As noted, only one of the blades from Project X Japanese does not use a maru laminate T10 blade but instead is made from a complex tri steel 7 layer lamination known as Soshu Kitae – with hard 1095 carbon steel edges, spine and sides, a core of shock resistant 1045 carbon steel sandwiched between two more layers of tough 1060 carbon steel and capped of at the mune with 1095 (we said it was complex)!

The end result, a very lively blade with lots of activity and interplay between the lamination and hamon.

Using the exact same fitting options as Forge Direct, the ONLY difference between Forge Direct and Project X is the blade. So essentially which one you choose depends on how traditional you want the actual cutting blade to be..

Using the exact same fitting options as Forge Direct, the ONLY difference between Forge Direct and Project X is the blade. So essentially which one you choose depends on how traditional you want the actual cutting blade to be..

The Main Differences

Obviously as we have already noted, the main difference between each line are the blades. While all the blades and fittings are made at the exact same forge, the basic entry level Ryujin blades are made by blue collar workers, the elite Ryujin – apprentices of the Masters (and are classified as Tier II blades). Forge Direct and Project X – all are made by rank 1 or rank 2 certified Master smiths (including the actual forge owners themselves)..

In terms of actual blade performance, Ryujin swords are essentially decent entry level beater blades, Forge direct are extremely versatile, beautifully balanced high end martial arts grade and Project X – the closest to an actual Nihonto (in terms of performance – due to the slightly harder edge, it cuts slightly better than Forge Direct. Not a huge difference in terms of practicality, but it is most certainly the most traditionally forged of them all).

Because all the swords are made at the same forge – for the high end stuff in Forge Direct and Project X the fittings are the same. While the Ryujin swords ALL use the most inexpensive fittings possible, both Forge Direct and Project X use the BEST fittings available (Tier III) – and there is literally NO DIFFERENCE between the fitting choices for Forge Direct and Project X. The ONLY Difference now is the quality and complexity of the blade itself..

So let’s look at what you can get for the fittings and the various custom options.

Variations of Customization Options By Line

The Ryujin line is the most basic, with a 10 available tsuba choices, 9 available tsuka (handle) color choices and 10 different types of saya. You cannot select the color of the rayskin, nor length of the blade – though there are models such as a bo-hi (fullered) and no-hi model.

The Forge Direct Custom Katana and Project X conversely have MANY customization options. Due to the need to pre-made all the saya many months in advance, the blade length is set to 28″ nagasa and cannot be adjusted (the handle length can be lengthened or shortened, but not the actual blade or saya).

These lines also have some of the Ryujin tsuba sets available (12 sets total) but also add in 28 elite work hardened copper sets, some which are the same as the (retired) SBG custom line. There are 5 ito handle colors available (6 if you include the optional ‘bad boy’ black leather wrap), 3 colors of rayskin (white, black and red), 5 different types of hard wearing silk sageo, and 8 elite styles of saya (some incurring a minor additional fee depending on complexity):

Price and Lead Time Variations

The final main differences other than blade quality is of course

- price, and

- how long it takes to receive your custom design from ordering to it arriving a at your door.

Obviously, being assembled from parts already shipped to the USA, The Ryujin Custom Sword Line is the fastest and the most affordable, starting at $249.99 for a limited option model and up to $499.99 for the Elite Choji Midare version (which is close to Forge Direct in blade quality, but made by senior apprentices of the master smiths rather than the masters themselves).

As mentioned, all Ryujin swords are actually assembled in a workshop based in Chino, Los Angeles – so when it comes to speed and price, they win hands down.

The Forge direct Elite line are made to order by master smiths and shipped directly from the forge. Prices start at around $650 for a Wakizashi and $700 for a custom Katana, though optional extras (at subsided pricing) are available. Available all year round, they are usually completed and shipped out within 6-8 weeks though delays of a couple of extra weeks are not unheard of as some parts take longer to bring in or create than others and may be effected by long national holidays.

Project X Japanese starts at $850 for the T10 hi polish and $1000 for the Laminated Katana plus any additional optional extra upgrades you might select and like forge direct, are made to order. While to the uninitiated they may seem expensive, they are actually under priced and quite risky for us as the profits are minuscule ($1800+ would be a fair price for these swords – $1000 is almost as much as they cost to make and ship).

Biggest problem is due to the complexity of the forging process, the turn around time for these is typically 2-3 weeks longer to make that forge direct and delays of a few additional weeks are quite common (as the forge is very pedantic about their QC, which is not a bad thing – but may cause a slightly longer delay than expected, so if you need one of these by a specific date, make sure to get your order in as early as possible).

Conclusion

So here is a quick summary. Except for the Soshu Kitae laminated blades from Project X, all the blades are made from the same type of steel, differentially hardened T10 – but at different levels of refinement and therefore, at different price points.

The component choices are the same at the higher end and use the best components available, while Ryujin goes the other way and uses the least expensive fittings with all the money invested in the actual blades.

We would like to think that within these three lines there is something for everyone, for every taste and every budget. True enough, these are not 100% custom swords – but over the years we have seen so many different variations and unique combinations that suggest that even with the same brand you can create wildly different looking designs.

It never ceases to amaze me the imaginative creations our customers come up with to creating a truly unique sword that best suits their own individual style from the available options. Even on the Ryujin line, it is incredibly rare to see two swords exactly the same – and I think that this freedom of choice, to design your own personal sword, is what makes our custom katana projects so rewarding and so much fun.

Enjoy the process, and if you have any questions just let us know. We are always happy to answer your questions.