Those lucky few who pre-ordered the stunning Dragon Dao sword by Master Xiaolong are even luckier now than ever before..

As it turns out, the current stock we have available – which is the last time these swords will ever be offered shipping from North America, simply weren’t quite as perfect as they should have been.

Maybe it was just bad luck, as to be honest the quality isn’t really ALL that bad.. But the few imperfections are enough that we cannot comfortably sell them at the already discounted price of US$1,799..

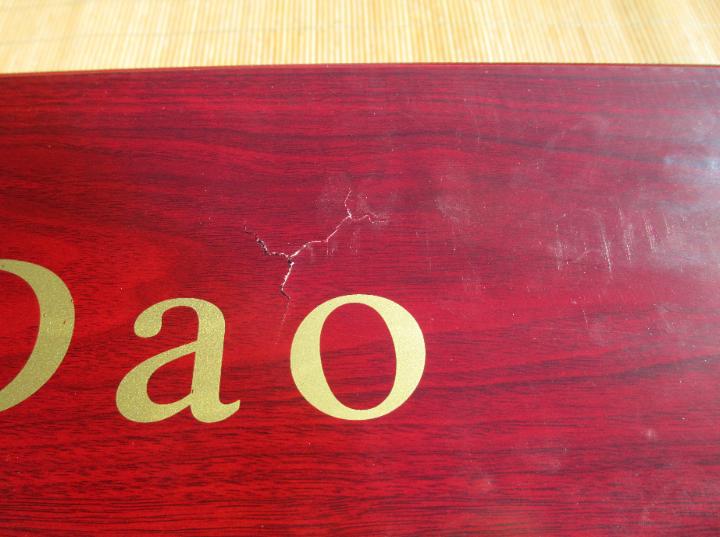

For example, some of the swords have come in with some patina on them from shipping – some people may like the look, others may want to clean it off with some elbow grease. Here is a photo showing the worst of the worst..

I guess you could call it an “antiqued” look

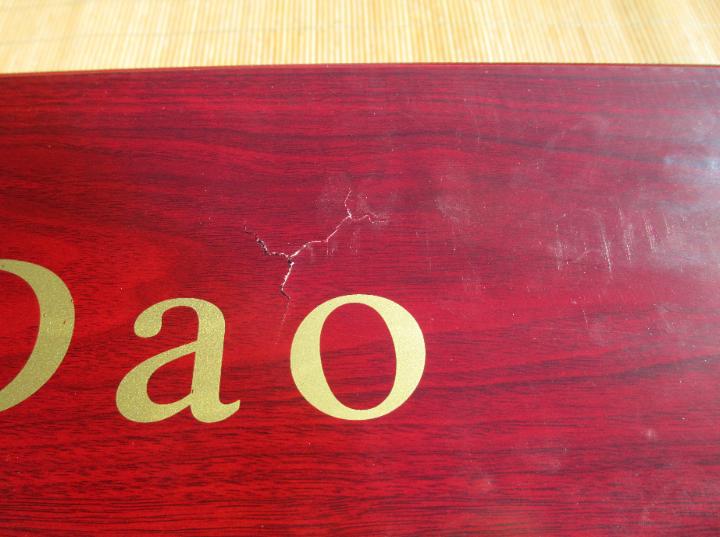

Also, some of the nice wooden display boxes got damaged in transit – hardly a deal killer, but definitely annoying. Here is what I mean:

It’s just a box after all, some are ok, others with a ding..

Swords with these minor cosmetic issues we have designated scratch and dent level one and they are available to be shipped after a quick clean up for $500 less than the usual price..

The second level of cosmetic issues may also have the patina, but also some discoloration of areas of the full rayskin wrapped scabbard like so:

Not pretty, but only there if you look for it. Level 2 Scratch and Dent..

And/or they may also have an annoying scratch that happened during polishing like this:

Tis but a scratch.. But a scratch that can save you $800!

These details are only really visible if you are looking for them, but are enough to lower the price down $800 and are designated level 2 scratch and dents (just $999.99).

Plus from now until the end of November, you can save another $100 by using the coupon code:

100off

None of the issues are anything but cosmetic and the amount of money we are discounting these by really is more a sense of our own disappointment than anything else..

So what can I say, if you are willing to trade off for a few imperfections to save up to $900 on a sword that, despite these cosmetic flaws are STILL heirloom quality (heck, we could argue that some of them look more like antiques ahead of their time!) – well, you know where to buy them..

Stocks are limited and once they are gone they are gone for good, we took to much of a hit selling the, off at this well below wholesale price – so if you are fast, our misfortune could well be your lucky chance..

Click here for more information

The damage is cosmetic and pretty minor in the grand scheme of things for a sword that is one of the most fearsome two handed cutters EVER seen in North America. And the savings, kind of crazy!

Grab a bargain while you can..