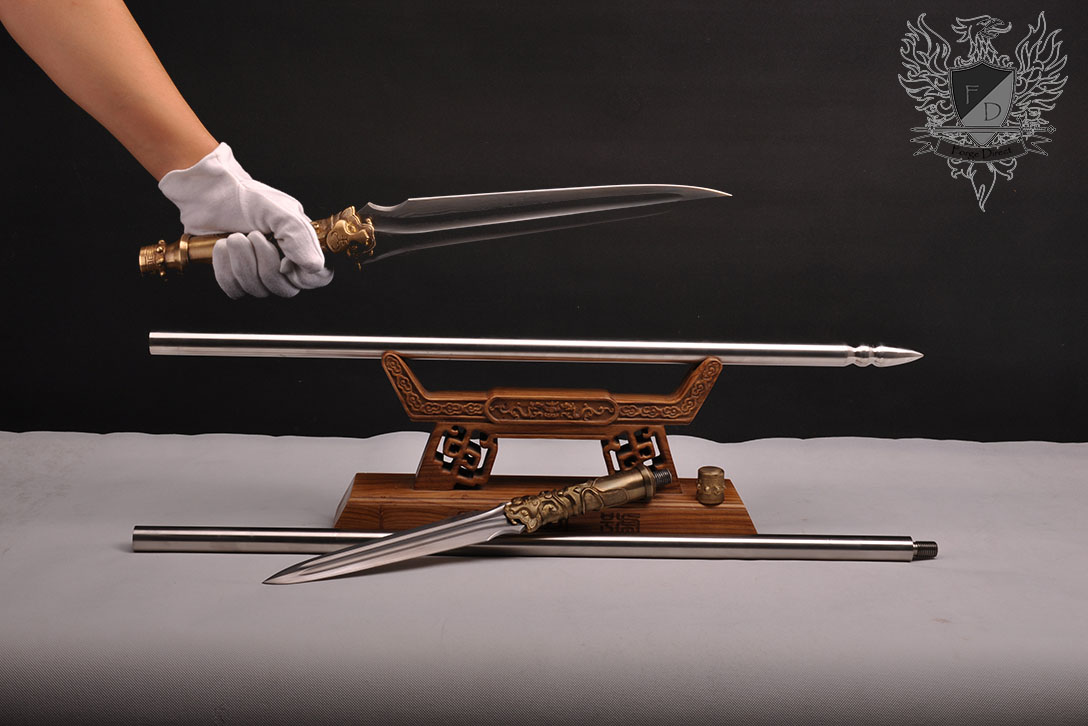

Limited Re-release and now with CUSTOM options!

Project X Subscribers, check your email!!

Last offered in July 2017, it has taken nearly 2 years to get to this point, but we are here with a limited re-release of our very best traditional Japanese swords from Project X!

With stunning Soshu Kitae laminated master smith forged blades decked out in the best fittings possible with no expenses spared (i.e. FULL rayskin samegawa wraps on the handles, alternating silk ito made using hishigami triangles, buffalo horn inserts on the saya – you name it, they have it) the true market value of these swords is easily closer to $2000 than the average asking price of $1000.

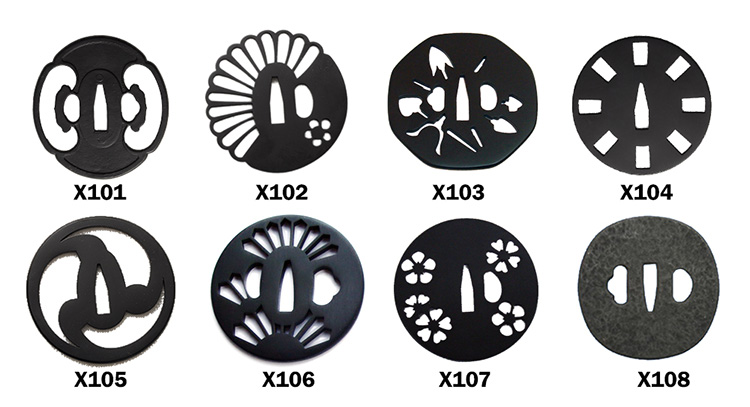

But even better, each sword has a carefully chosen selection of custom options and custom fittings that match the designs theme so you tweak it to your own personal tastes without accidentally creating an ugly sword. But you are also free to use any and all of the custom options from the other designs.

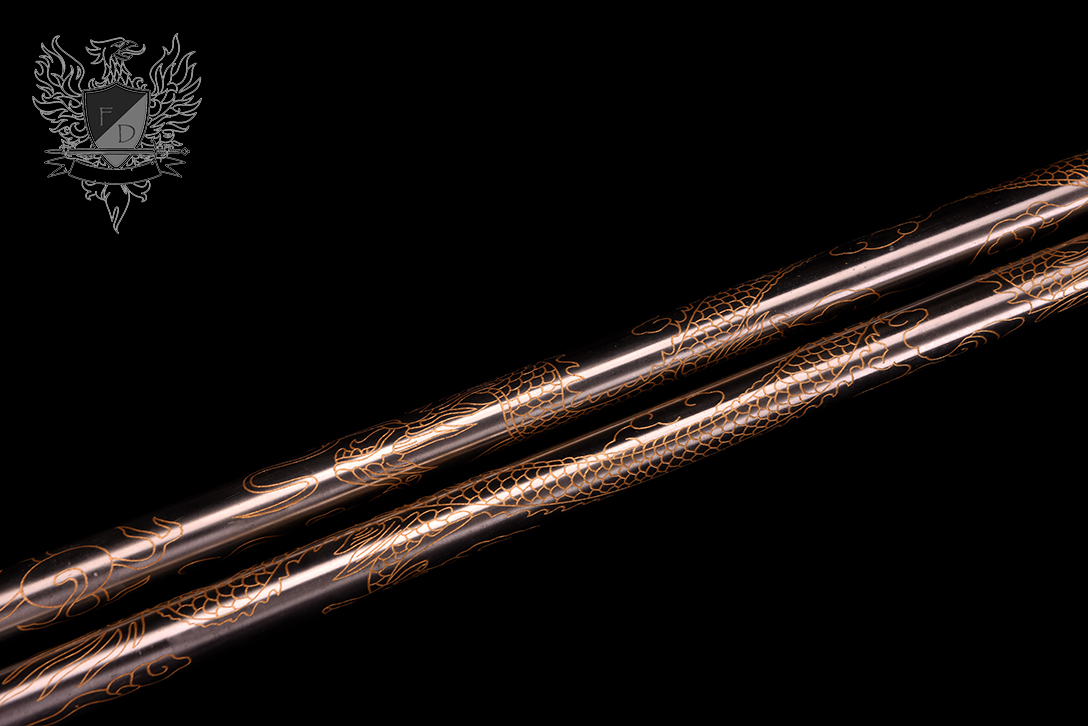

You can see all the custom options on a new page on the blog here plus there are also a few additional paid custom options to take the design to the next level such as black leather ito wrap (naturally also done with hishigami and sporting a full rayskin wrap underneath), Dragon Horimono engraving on the blade or mother of pearl inlaid saya..

As it literally took two years of wrangling with the forge for them to allow this, this re-release is limited to 20 swords only – and only if everyone is happy with the results (i.e. the Forge, SBG and those who are quick enough to secure one) then we will offer them all year round..

QC standards will be applied as if they ARE $2000 swords, but with an average price of $1000 the value for money factor is off the charts (especially as you cam also request additional minor customizations such as gyaku menuki placement, kissaki length, etc).

If you want to get in on this special re-release, keep your eye on the order progress bar that will appear once we reach 20% capacity..

Because when it looks like this:

You probably will only have a day or less to secure one before the opportunity slams shut.

Lead time between placing your order and receiving your sword is 4-6 weeks, so check out all the original models by clicking the link below:

Work has already commenced on the final 10 swords of the

Work has already commenced on the final 10 swords of the